LH Evaporator

Engineering for energy saving

LH Evaporator

Engineering for energy saving

Turbo Compressor

LEHENG compressor use unrivalled tailor-made impeller to meet your stringent performance requirements

-

首页

-

Products

-

MVR Turbo Compressor

-

Pipeline Pressurized Turbo Compressor

- Pipeline Booster Compressor

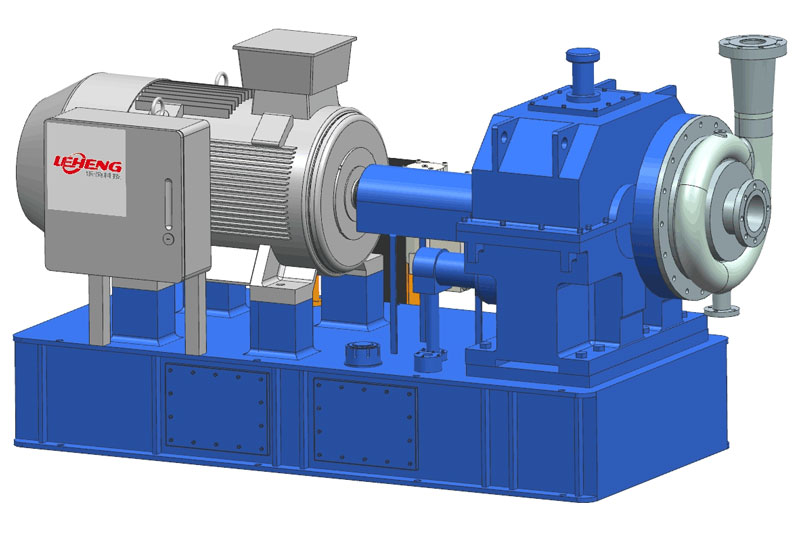

Pipeline Booster Centrifugal Steam Compressor

Working Principal of LH Pipeline Pressurized Steam Compressor:

The structure design of Pipeline Pressurized Steam Compressor is same as gearbox drive steam compressor, driven by motor with speed up gearbox. Pipeline Pressurized Steam Compressor is mainly used for RE-compression of steam at high pressure and high temperature. To fit for the high pressure and high temperature steam, the material selection of the main parts is very different from the conventional Gearbox drive steam compressor.

Basic parameters LH Pipeline Pressurized Steam Compressor:

| Item | Parameter range |

|---|---|

| Mass Flow (MVR system evaporation): | 1~200tons/h |

| Volume Flow: | 3000~280000 m³ /h |

| temperature rise of saturated steam: | 6~24 ℃ |

| Impeller rotation speed: | 5,000~40,000RPM |

| Max. compression ratio: | 3.5 |

| Remark: specialized for high pressure, high temperature steam re-compression. | |

Technology Advantages for LH Pipeline Pressurized Steam Compressor:

- Compressor inlet can accept pressure above 200Kpa; the fresh steam can be directly compressed to increase its enthalpy;

- Central heating is becoming more and more popular, pipeline pressurized steam compressor can break through the pressure limitation of the heating air source, flexible customize the pressure required, seamlessly connect thermal power plants to general industrial users;

- Structure design is same to Gearbox drive steam compressor;

- Precise design of impeller can improve the isentropic efficiency up to 85%, however, normal roots compressor isentropic efficiency will not more than 60%;

- Flow capacity can be customized, from small capacity 5tons/h to 200tons/h.

- In severe working conditions, impeller can also use TC4 titanium alloy with light quality, high strength and good corrosion resistance

- As the core component of steam compressor, impeller is customized according to client’s request. The design of the impeller strictly carries out various mechanical calculations, and the complex processing flow ensures the efficiency and reliability of the impeller

- Advanced end teeth design between impeller and high speed shaft, ensures the better centering effect, and reliable torque transmission.

- According to requirement, guide vane regulating system and frequency convertor is available to ensure the high efficiency of compressor, from 50%~120%; Simple regulating system with easy design, stable working performance and longer lifetime.

Different customers with different process, the same process will have different parameters; our company has various structures of products, with different rotation speed design, with different driven system to meet the client’s requirement.