Recently, the 17th China International Battery Technology Exhibition (CIBF2025) concluded successfully at the Shenzhen World Exhibition & Convention Center.

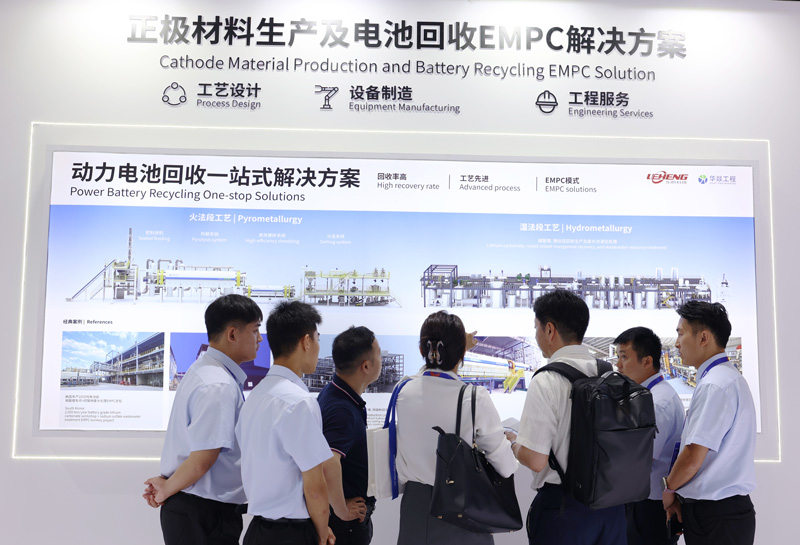

At the exhibition, Hebei Leheng Energy-saving Equipment Co., Ltd. highlighted its "Cathode Material Production and Battery Recycling EMPC Solutions" as the core theme, demonstrating one-stop technological innovations spanning cathode material R&D, intelligent and efficient production, and green recycling. These advancements inject new momentum into the sustainable development of the new energy industry.

Deepening Circular Economy: Building a Green Closed Loop for Battery Lifecycle

Under China’s "Dual Carbon" strategy, power battery recycling and resource efficiency have become industry focal points. Hebei Leheng’s showcased Hydrometallurgy-process battery recycling solutions leverage proprietary evaporation crystallization technology to achieve high-efficiency recovery of critical materials such as lithium carbonate, nickel, cobalt, and manganese. Simultaneously, the company advances wastewater resource treatment, significantly reducing environmental impacts in production processes.

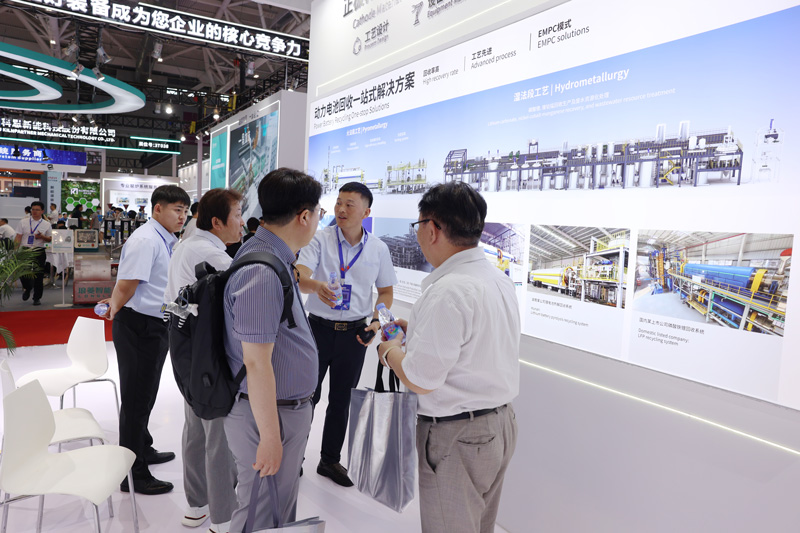

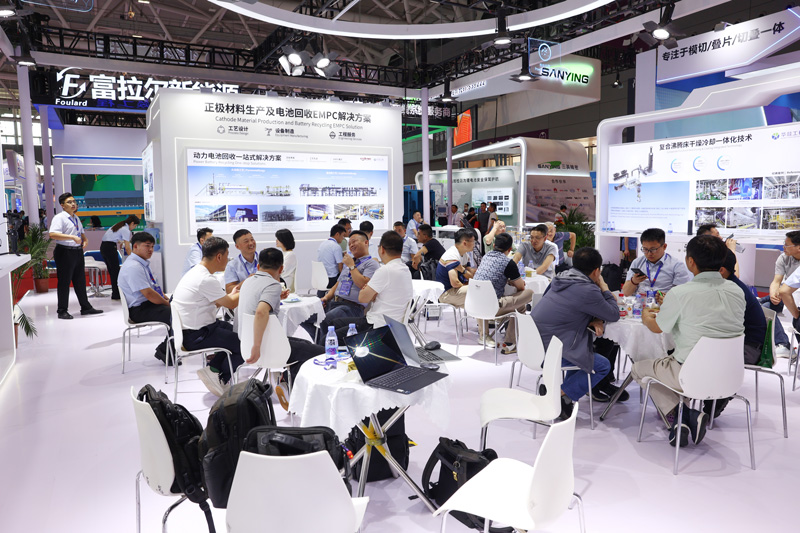

A series of case studies presented at the exhibition underscored Hebei Leheng’s technical expertise in this field, attracting extensive attention and fostering in-depth exchanges with enterprises across the upstream and downstream of the industrial chain.

Empowering Low-carbon Manufacturing: Technological Innovation Drives Energy Efficiency

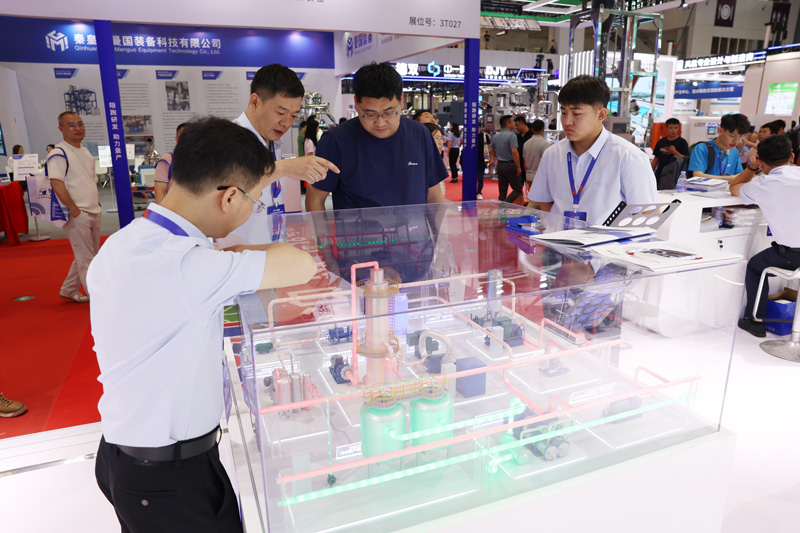

To address energy consumption challenges in new energy manufacturing, Hebei Leheng introduced full-process energy-saving solutions: Steam Energy Optimization: Technologies such as steam pressure reduction, temperature-lowering power generation, and heat pump distillation reduce production energy consumption by over 40%.

Revolutionized Air Compression Systems: Steam-driven systems replace traditional electric air compression, dramatically enhancing energy utilization.

High Efficient Crystallization Processes: MVR (Mechanical Vapor Recompression) evaporation crystallization and vacuum continuous cooling crystallization systems help enterprises save energy, improve product quality, and enhance production sustainability.

Our technologies and products have served hundreds of global enterprises, demonstrating the seamless integration of green manufacturing and economic benefits.

Industry Recognition: Technical Leadership Shapes Future Ecology

During the exhibition, Hebei Leheng’s booth became a hotspot for professional visitors and industry experts. Representatives from domestic and international enterprises expressed strong interest in the company’s solutions, with leading industry players engaging in in-depth discussions on potential collaborations.

Looking Ahead: Continuous Innovation for a Zero-carbon Vision

As a leading MVR steam compressor and system integration supplier in the lithium battery industry, Hebei Leheng collaborates with AGT Group members such as Zhejiang Yaguang and Shandong Huayi Engineering to share resources, co-develop markets, and deliver optimized, energy-efficient full-process solutions for the new energy sector. By empowering customers with low-carbon transition strategies, the company aims to collaborate with global partners in building a more efficient and cleaner energy ecosystem.