LH Evaporator

Engineering for energy saving

LH Evaporator

Engineering for energy saving

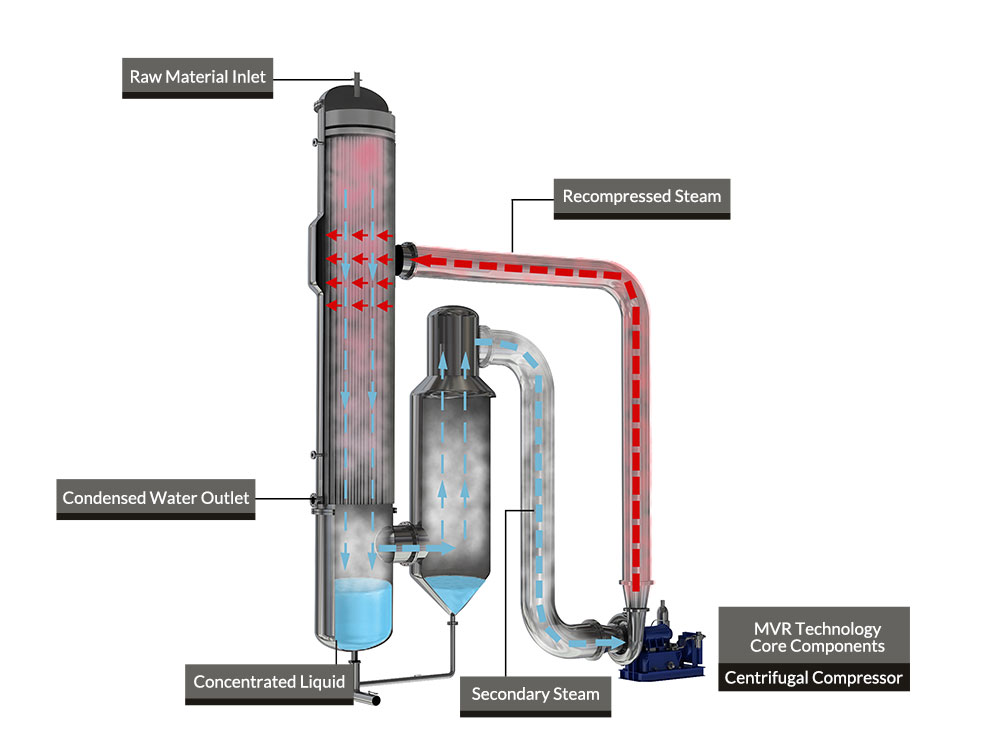

Mechanical Vapor Recompression(MVR) Evaporator

MVR Evaporator Working principle:

MVR is called Mechanical Vapor Recompression. It use the centrifugal compressor to re-compress the secondary vapor(low temperature and low pressure) which is evaporated from the liquid material to rise its temperature and pressure, so as to reuse it as heating source to evaporate the liquid material again. The process is to convert a small amount of electric energy to more heat energy. Theoretically, compared with multi-effect evaporator, it can save more than 50%~80% energy consumption and 90% cooling water.

System Composition:

Composed of a preheater, heat exchanger, separator, vapor compressor, vacuum pump, circulating pump, operating platform, control cabinet, and other accessories.

Main Features:

- MVR energy-saving evaporation technology is the most advanced technology at present, only need a very small amount of steam (small steam required during start-up, almost no need steam during normal operation), greatly reduce the operation cost, reduce environment pollution.

- Compared with traditional evaporators, MVR evaporator temperature difference is much smaller, can achieve moderate evaporation, greatly improve product quality and reduce fouling.

- No need condenser or only a small area of the condenser required, the structure and process is very simple, fully automatic operation and continuous operation, safe and reliable

- Equipped with CIP cleaning pipeline, on-site cleaning, the whole set of equipment is easy to operate, no dead angle.

- The material can be evaporated at low temperature (evaporation temperature 50℃~100℃) and no foam is produced. The material is uniform material, no running material, not easy to coking, minimum denaturation for heating material.

- The installation space of the MVR evaporator is about two times of traditional multi effect evaporator; the equipment investment amount of MVR system is larger, but the operation cost is much lower than the traditional multi effect evaporator.

- Automatic operation system is necessary to protect the equipment, to avoid the MVR malfunction caused by wrong operation.

- In some special areas where the steam cost is very low and the electricity price is very high, the economic advantage of MVR evaporator is not obvious, traditional evaporator is recommended.

Performance comparison between MVR Evaporator and traditional evaporator

| S/N | Single effect evaporator | Multi effect evaporator | TVR evaporator | MVR evaporator |

|---|---|---|---|---|

| Energy source | Using steam heating Steam pipe network Need boiler |

Using steam heating Steam pipe network Need boiler |

Need high pressure steam to drive, Need boiler |

Using electric power, no need steam pipe network close loop circulation system |

| Energy consumption | 1 tons steam for 1ton water evaporation | 0.3~1tons steam for 1ton water evaporation | Based on traditional multi effect, one more effect is used with high pressure steam drive | The most energy saving technology at present |

| Operation cost | Much higher | More energy saving | Lower | Lowest |

| Footprint | smaller | bigger | bigger | smaller |

| Product quality | Short residence time, Bigger temp. difference lead to easy scale. product quality not stable |

Longer residence time, Bigger temp. difference lead to easy scale. product quality not stable |

Short residence time, Smaller influence on product quality |

Short residence time, Low temp. evaporation, Minimum impact on product quality |

| Control type | Semi-automatic | Full automatic Uninterrupted evaporation |

Full automatic Uninterrupted evaporation |

Full automatic Uninterrupted evaporation |

Latest News

Hebei Leheng Energy-saving Equipment Co., Ltd. Showcases at CIBF2025 Shenzhen International Battery Fair:Empowering Green Energy Transition with Battery Recycling and Intelligent Energy-saving Manufacturing Solutions

Recently, the 17th China International Battery Technology Exhibition (CIBF2025) ...

Energy Conservation and Consumption Reduction Drive Industrial Upgrading Energy Cascade Utilization Empowers Green Development. Leheng Energy Showcases Integrated Energy-Saving Solutions at the 66th CIPM Expo

The 66th China International Pharmaceutical Machinery Expo (CIPM) concluded succ...