LH Evaporator

Engineering for energy saving

LH Evaporator

Engineering for energy saving

Turbo Compressor

LEHENG compressor use unrivalled tailor-made impeller to meet your stringent performance requirements

-

首页

-

Products

-

MVR Turbo Compressor

-

Direct-drive Turbo Compressor

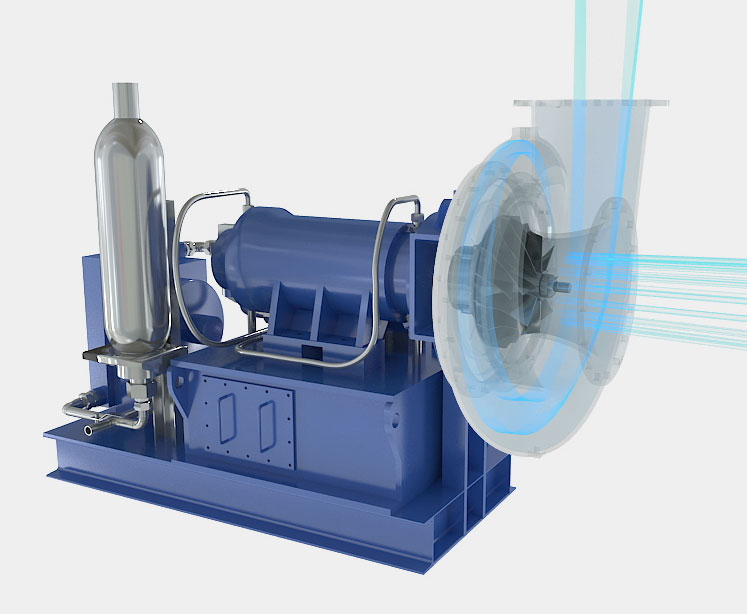

- High Speed Direct Drive- Centrifugal Steam Compressor

High Speed Direct Drive- Centrifugal Steam Compressor

Working Principal for LH High Speed Direct Drive Centrifugal Compressor:

- High speed motor direct drive steam Compressor is driven by special customized high speed motor.

- High speed impellers press the steam flow out the impeller under centrifugal force.

- Meanwhile, the upstream steam will come to fill the impeller. Because of the impeller’s high speed rotation, the steam flow velocity will be accelerated and leave the impeller.

- Steam flow speed reduced after going through diffuser, kinetic energy is converted to hydrostatic energy, pressure increases and temperature rises.

Centrifugal Steam compressor is core equipment with high technology, which play important role in MVR evaporator system. Compared with Roots compressor, steam compressor developed by our company, have many advantages like wide working range, easy maintenance, lower noise and better reliability etc.

High-speed motor Direct Drive centrifugal compressor basic parameters:

| Item | Parameter range |

|---|---|

| Mass Flow (MVR system evaporation): | 1~10tons/h |

| Volume Flow: | 3000~14000 m³ /h |

| temperature rise of saturated steam: | 6~16 ℃ |

| Impeller rotation speed: | 5,000~40,000RPM |

| Max. compression ratio: | 1.8 |

|

Remark:

|

|

Technology Advantages for LH High Speed Direct Drive Steam Compressor:

- High speed motor direct drive design: special customized high speed motor drive the rotation of impeller directly. The impeller speed can up to 5,000~40,000rpm, faster than ordinary jet plane;

- Limited by the stability requirements of high speed motors, high speed direct drive steam compressor is commonly used in small amount of processing conditions, eg. 5~ 10 tons/h;

- Widely used in MVR evaporation concentration system for Chinese and western medicine application;

- Cooling system: conventional fan cooling is not suitable for cooling the high speed motor. Water circulation cooling system is designed for cooling the motor, bearings and other components;

- compression ratio customized according to working condition, general 1.3~1.8;

- Temperature rise customized according to working condition, general 6~16℃;

- Precise design of impeller can improve the isentropic efficiency up to 85%, however, normal roots compressor isentropic efficiency will not more than 60%;

- Compared with gearbox drive steam compressor, more compact design, easy structure and easy maintenance.

- Steam compressor volute is usually made from stainless steel casting or welding, with strong corrosion resistance and better stability;

- Impeller made from precipitation-hardening stainless, with more than 1100MPa tensile strength and good corrosion resistance

- In severe working conditions, impeller can also use TC4 titanium alloy with light quality, high strength and good corrosion resistance

- As the core component of steam compressor, impeller is customized according to client’s request. The design of the impeller strictly carries out various mechanical calculations, and the complex processing flow ensures the efficiency and reliability of the impeller

- Advanced end teeth design between impeller and high speed shaft, ensures the better centering effect, and reliable torque transmission.

- According to requirement, guide vane regulating system and frequency convertor is available to ensure the high efficiency of compressor, from 50%~120%; Simple regulating system with easy design, stable working performance and longer lifetime.

- Different customers with different process, the same process will have different parameters; our company has various structures of products, with different rotation speed design, with different driven system to meet the client’s requirement.