The 66th China International Pharmaceutical Machinery Expo (CIPM) concluded successfully at the Chongqing International Expo Center. Centered on the theme of "Comprehensive Energy Cascade Utilization Solutions for Pharmaceutical Enterprises," Leheng Energy highlighted its cutting-edge MVR evaporation and crystallization technologies, as well as innovations in steam energy conservation, waste heat and pressure recovery, offering new pathways for the green transformation of the pharmaceutical industry.

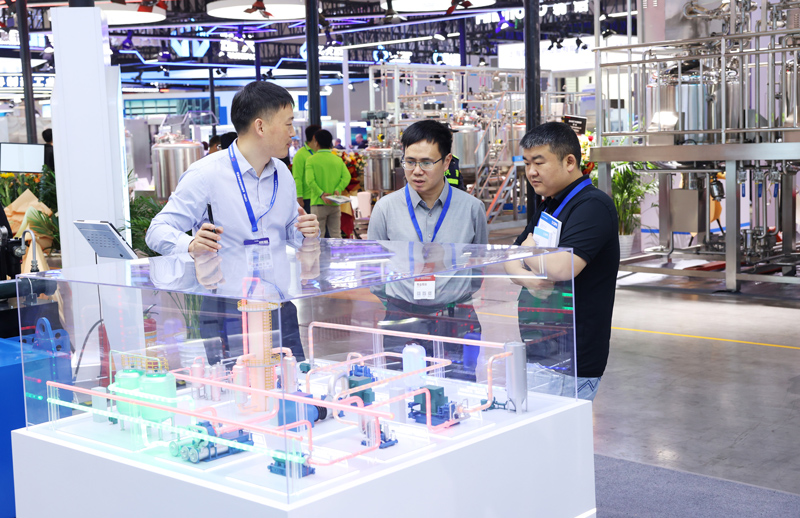

At the expo, Leheng exhibited its MVR Traditional Chinese Medicine (TCM) Concentration Solution, tailored to the characteristics of the TCM and plant extraction industries. The solution incorporates Leheng’s self-developed high-speed direct-drive two-stage centrifugal steam compressor, which meets the technical demands of MVR concentration in TCM processing through its superior structural and operational performance, filling the gap for low-energy-consumption equipment in this field.

Additionally, Leheng presented its MVR High-Salt Wastewater Resource Recovery Solution, integrating full-process technologies such as evaporation crystallization, freeze crystallization for salt separation, centrifugation, drying and packaging. Through customized MVR compressor units and intelligent coupling design, this solution achieves wastewater reduction, resource recovery, and energy-efficient treatment.

Under China’s "Dual Carbon" goals, Leheng has developed a comprehensive energy cascade utilization system centered on turbomachinery technology, systematically unlocking energy-saving potential across the entire pharmaceutical production chain.

Heat Pump Distillation Retrofit

Addressing the high steam consumption and low efficiency of traditional distillation processes, Leheng introduced its heat pump distillation retrofit solution, combining MVR steam recompression technology with mature distillation processes from Yaguang.. By pressurizing and reheating tower-top process gas for reuse in tower-bottom heating, the solution achieves closed-loop energy circulation, reducing operating costs by over 30% with a payback period of less than two years.

Steam Pressure Reduction and Cooling Power Generation (Replacing Steam temperature and Pressure Reducing Valves)

During the high-pressure steam pressure reduction and transportation section, the traditional temperature and pressure reducing valve only uses the thermal energy of steam, and the pressure energy of steam is used to do work on the spray water to turn it into steam, which has low energy utilization efficiency. Leheng's steam pressure reducing turbine can use the high-pressure energy of steam and convert it into mechanical energy to drive the generator to generate electricity or tow other power machinery, which not only achieves the temperature and pressure reduction of steam, but also realizes the efficient utilization of energy.

Process Gas Residual Pressure Recovery

For residual pressure waste in pharmaceutical processes (e.g., fermenter tail gas, compressed air, nitrogen), Leheng deploys gas expansion turbines to convert pressure into mechanical energy for directly driving pumps, fans, or generating electricity. In one case, even with a minimal 25 kPa pressure difference and 2000 Nm³/h flow rate, the turbine unit stably outputs 20 kW of power, yielding annual revenues exceeding CNY 60,000.

Amid China’s "14th Five-Year Plan" initiatives to promote green API production and enhance water efficiency in the pharmaceutical industry, Leheng will continue advancing energy cascade utilization technologies anchored in turbomachinery and MVR system innovation. Beyond providing solutions like TCM MVR concentration and near-zero discharge for high-salt wastewater, We are building a multi-industry energy cascade utilization service ecosystem spanning pharmaceuticals, new energy and petrochemicals. This drives industries toward high efficiency, low carbon and sustainable development, accelerating the realization of China’s "Dual Carbon" strategy.