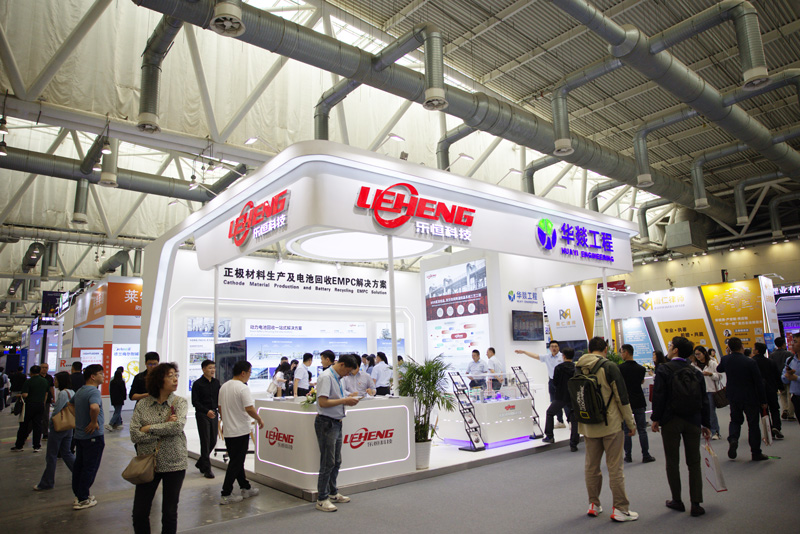

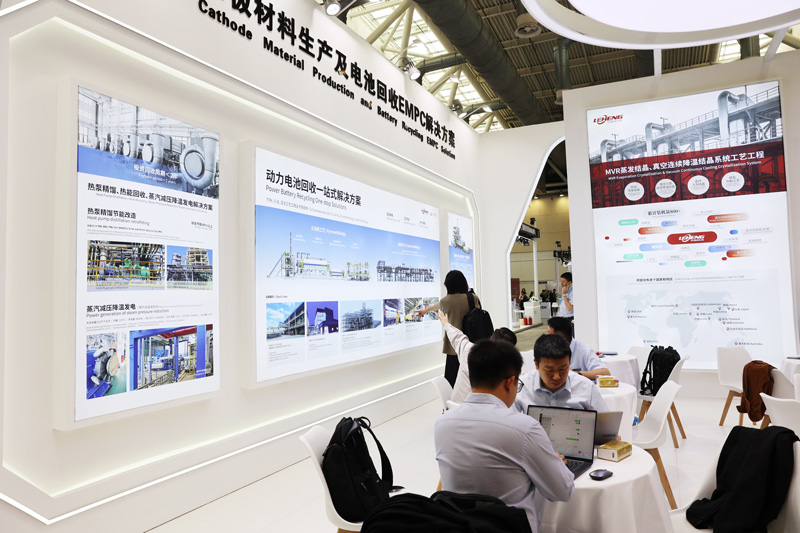

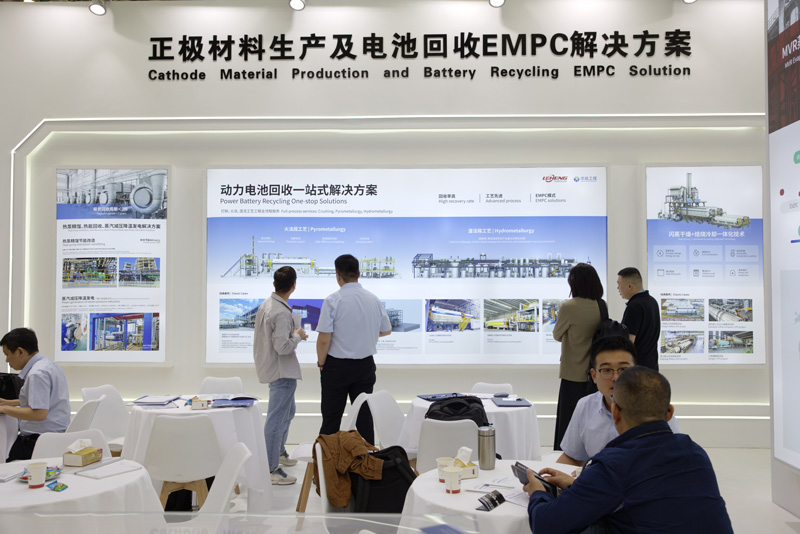

Recently, the 10th China International New Energy Industry Expo (CLNB 2025) concluded successfully at the Suzhou International Expo Center. Leheng Energy Saving, in collaboration with Shandong Huayi Engineering Service Co., Ltd. (a member company of Zhejiang Yaguang Co., Ltd.), showcased its theme of "Green Manufacturing · Circular Symbiosis," focusing on intelligent manufacturing of lithium battery cathode materials and battery recycling technologies. The event presented a comprehensive EMPC full-industry-chain solution spanning R&D, production, and recycling, conveying the concept of sustainable development through service innovation.

Technology-Driven: Building Full-Industry-Chain Service Capabilities for Lithium Battery Materials。

Leheng Energy Saving launched multiple innovative technical solutions centered on lithium battery material production and circular recycling technologies to help customers achieve high-efficiency and low-carbon operations.

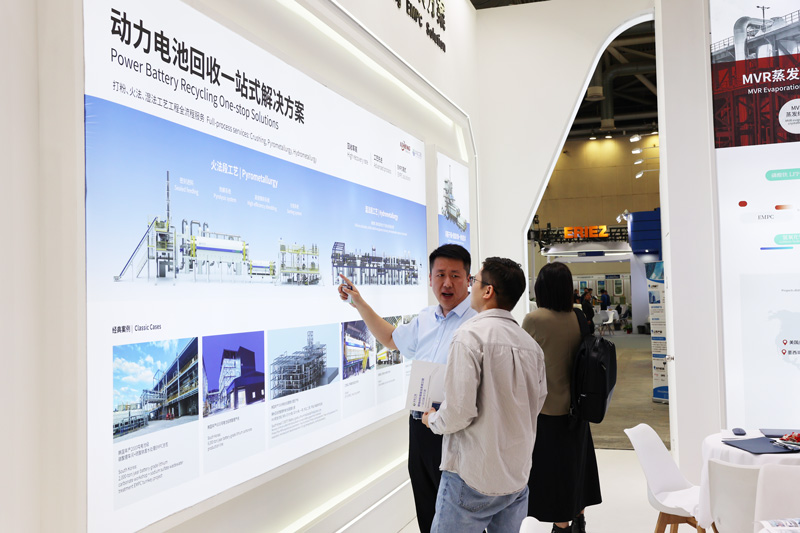

We introduced a "Powdering-Pyrometallurgy-Hydrometallurgy" full-process recycling technology to enhance material regeneration efficiency and reduce resource waste. Innovative safe dismantling technologies ensure efficient conversion of retired batteries into renewable resources.

The synergistic application of heat pump distillation technology and steam residual pressure power generation technology reduces production energy consumption costs and shortens investment payback periods.

MVR evaporation crystallization and vacuum continuous crystallization systems adapt to complex working conditions, improving the quality of cathode materials while lowering costs.

The integrated design of flash drying and calcination cooling adopts compact, energy-saving layouts and intelligent temperature control to minimize energy consumption.

Scenario-Based Demonstration: Achieving Energy Efficiency through Impeller Machinery Drive Technology

Through on-site model demonstrations, Leheng presented a comprehensive energy cascade utilization solution centered on impeller machinery.

By simulating industrial processes, the exhibition visually demonstrated how low-grade heat sources and high-pressure gas/steam energy can be converted into usable energy. This approach optimizes factory energy structures and reduces operational costs through energy cascading.

Technology-Centric Approach to Fulfill Green Missions

Leheng Energy Saving remains committed to "driving green development through technology." The solutions showed not only meet customer demands for cost reduction and efficiency improvement, but also aim to reduce carbon footprints across the entire industry chain, supporting clients’ sustainable development goals.

Looking ahead, Leheng Energy Saving will continue to deepen its expertise, enhance full-industry-chain service capabilities and advance the construction of a green circular ecosystem for the new energy industry.