LH Evaporator

Engineering for energy saving

LH Evaporator

Engineering for energy saving

Crystallizer

Evaporation crystallization is used for clean separation technology and is considered as the most suitable technology in some wastewater treatment.

System Features

Wide range of applications, large heat transfer coefficient, easy to clean, resistant to structure, crystalline particles, and so on.

Application

- Vacuum salt making technology, brine well salt making, mineral salt separation of traditional salt industry.

- Suitable for the production wastewater with high salt, high COD and high boiling point in chemical plant pharmaceitical intermediates wastewater treatment.

- Concentration,crystallization and ZLD of Lithium battery and Three-dimensional precursor materials.

- Supporting membrane reactor, biological treatment and chemical treatment, chemical wastewater, sewage and other biological to achieve "zero liquid discharge" and solid waste recycling.

Product Advantages

- On the basis of heat transfer and evaporation, the evaporation crystallization process should also consider chemical process.

- According to the physical characteristics of different water quality, combined with the basic physical properties of the small test, through the analysis of the theoretical relationship between thermodynamics and dynamics of crystallization and the grain size of the product, the most suitable process and equipment selection are adopted.

- According to the solubility of different materials and the data of the metastable zone, the optimum concentration range of the crystallization process is analyzed, and the structure size of the evaporator and the type selection of the circulating pump are determined.

- In the process of crystallization operation, through crystallizing thermodynamics and kinetics theory balance, we control crystal processing parameters such as nucleation and growth rate, temperature and concentration, control crystal size and provide basis for mould selection.

- Can achieve continuously evaporation crystallization, strictly control crystal size and facilitate centrifugal separation; for inorganic salt products, the grain size is uniform and the yield of the product is high. Follow up the centrifuge, drying, packing and so on.

- Considering the recovery cost of solid salt, it is necessary to crystallize the products with high purity to improve the recovery value and reduce the operation cost of the wastewater with various ionic components. For example, sodium salt separation system of sodium salt wastewater.

Latest News

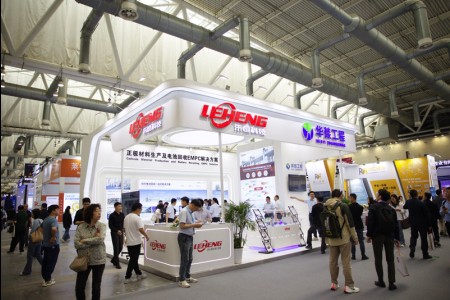

Hebei Leheng Energy-saving Equipment Co., Ltd. Showcases at CIBF2025 Shenzhen International Battery Fair:Empowering Green Energy Transition with Battery Recycling and Intelligent Energy-saving Manufacturing Solutions

Recently, the 17th China International Battery Technology Exhibition (CIBF2025) ...

Energy Conservation and Consumption Reduction Drive Industrial Upgrading Energy Cascade Utilization Empowers Green Development. Leheng Energy Showcases Integrated Energy-Saving Solutions at the 66th CIPM Expo

The 66th China International Pharmaceutical Machinery Expo (CIPM) concluded succ...