LH Evaporator

Engineering for energy saving

LH Evaporator

Engineering for energy saving

Products

Mechanical vapor recompression (MVR) evaporator & compressor from Leheng

-

首页

-

Products

-

Evaporator & Crystallizer

-

MVR Evaporator

-

MVR Rising Film Evaporator

- MVR Rising Film Evaporator

MVR Rising Film Evaporator / Climbing Film Evaporator

- Small heat transfer temperature difference, can achieve moderate evaporation, suitable for high viscosity and heat sensitive materials.

- Suitable for materials with higher evaporation temperature and higher viscosity (0.05-0.45Pa•s).

- No need steam condenser, simple structure process; continuous operation, safe and reliable.

- Shorter residence time and special structural design can reduce the growth of pollution and bacteria.

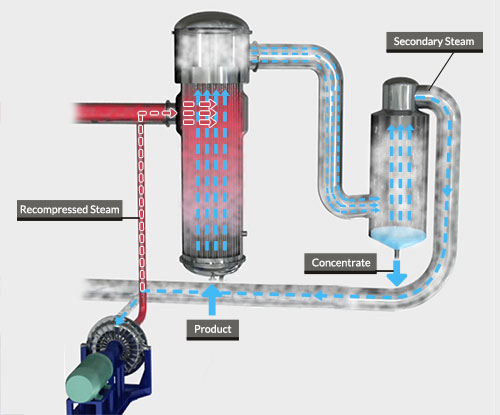

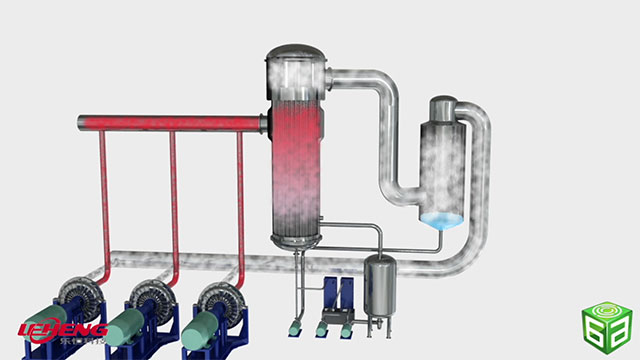

LH MVR Climbing Film Evaporator Working Principle

- After the material liquid preheated, it enter the evaporator from bottom, and enter the heating tube to vaporize rapidly.

- The generated steam rises at a high speed in the heating pipe.

- The solution is driven by the rising steam and rises in a film along the tube wall and continues to evaporate during the process.

- The mixture of vapor and liquid is separated in the separator and the liquid is discharged at the bottom of the separator.

- The used steam enters the steam compressor. After compressor process, the pressure increase and the temperature rise. As a new heat source, heat the material that needs to be evaporated.

MVR Climbing/rising film evaporator is improved model by MVR technology. By adding steam compressor and necessary match parts, the new model rising film evaporator can significantly increase the work efficiency and reduce operation cost.

MVR Climbing/rising film evaporator mainly composed of preheater, heat exchanger, separator, vacuum system, MVR steam compressor, cooling system, cleaning system and control system.

Product Features for LH MVR Rising Film Evaporator:

- In order to get rid of gravity and move upward, the liquid is highly turbulent, suitable for medium viscosity products.

- Based on the product cycles in broad conditions, operation is stable and efficient.

- Suitable for processing the evaporation concentration of dilute liquid with a large amount of evaporation, or sensitive & readily foaming solution;

- Not suitable for the solution with high viscosity, crystal precipitation and easy scaling.

Applications:

There is a wide range of applications for rising tube evaporators, including effluent treatment, production of polymers, food production, thermal desalination, pharmaceuticals, and solvent recovery.

Large Long-Tube Evaporators for Seawater Distillation. In terms of applications within these industries, rising tube evaporators are mainly used as reboilers for distillation columns, or as pre-concentrators or flash evaporators or pre-heaters designed to remove volatile components prior to stripping.