The 63rd (Autumn 2023) National Pharmaceutical Machinery Expo and the 2023 (Autumn 2023) China International Pharmaceutical Machinery Expo, from Nov. 12-15th,2023, has successfully concluded at the Xiamen International Expo Center.

As a professional pharmaceutical equipment and overall engineering solution supplier, Zhejiang Yaguang Technology Co., Ltd. participated in the exhibition with numerous equipment and engineering solutions. The products and engineering service covering pharmaceutical equipment, steam energy-saving transformation and waste heat and pressure energy recovery in the production process, pharmaceutical wastewater treatment, and other aspects.

The exhibition showcases the multi-disciplinary engineering solutions specially provided for the pharmaceutical industry, attracting a large number of visitors to our booth.

Deeply cultivate the pharmaceutical industry and establish a stable segmented market

AGT Group has been focusing on the pharmaceutical equipment field for many years and has become the drafting unit of national industry standards for (stopper & cap processing System) Rubber stopper washing machine and Agitated Nutsche Filter Dryer

So far, different series and numerous specifications of product groups have been formed in these two product fields. The Flip-Vertical Stopper & Cap Processing System exhibited this time is mainly designed for specific small and medium-sized batch rubber stoppers/aluminum caps, with a one-stop multi tank production method for the cleaning of rubber stoppers and aluminum caps Transportation provides a more flexible solution.

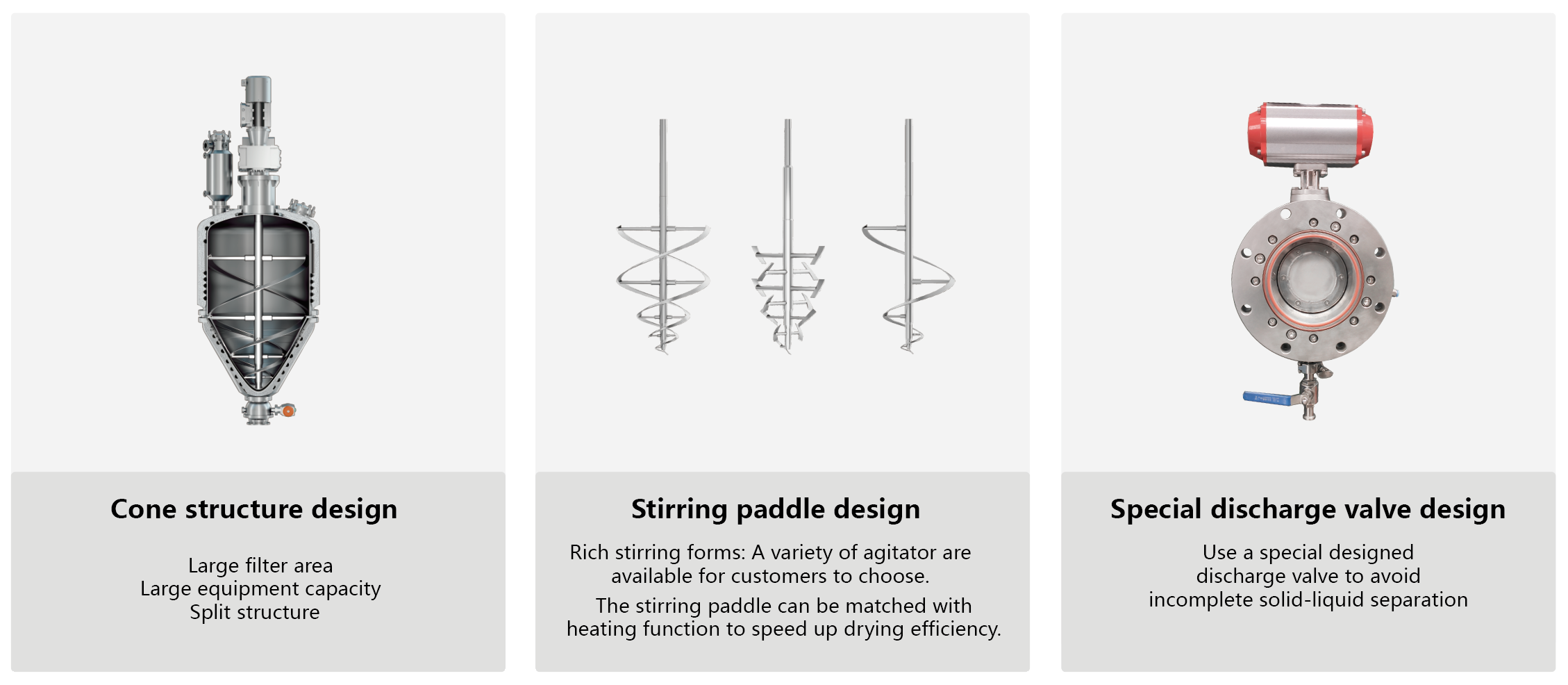

The exhibited Cylindrical-conical dryer & nutsche filter dryer has also aroused the strong interest of many visitors, and there have been constant consultations at the stand. As the latest member of the "AGT filter dryer", the Cylindrical-conical dryer & nutsche filter dryer not only has the advantages of larger unit area volume and larger filtration area, but also has AGT's "craftsmanship" in many details such as process design and product structure.

Hebei Daliheng Machinery Equipment Co., Ltd., a subsidiary of AGT Group, is committed to providing design, production, and research and development of pharmaceutical equipment and engineering systems solution. They can provide comprehensive powder process technology and containment solutions for pharmaceutical industry. AGT Group relies on its core technology advantages to integrate its upstream and downstream core processes, we are able to provide API full process and equipment solutions from feeding to packaging

Focusing on heat energy recovery to support the "carbon-neutral" global

Under the global trend of energy conservation, carbon reduction, and energy transformation and the guidance of China's carbon-neutral policy, how to achieve maximum energy utilization while reducing carbon emissions has attracted much attention.

AGT Group's subsidiary, Hebei Leheng Energy Saving Equipment Co. Ltd. , is a professional manufacturer of MVR evaporation equipment in China. Based on the key technology of MVR steam recompression, it provides thermal energy recovery and refined energy management solutions with impeller machinery technology.

The key equipment of MVR technology is the steam compressor. The steam compressor converts electrical energy into mechanical energy through an electric motor to drive the impeller to work. Then, the impeller works on the steam to convert mechanical energy into thermal energy, which compresses and heats up the secondary steam to increase its enthalpy value and achieve thermal energy recovery and utilization.

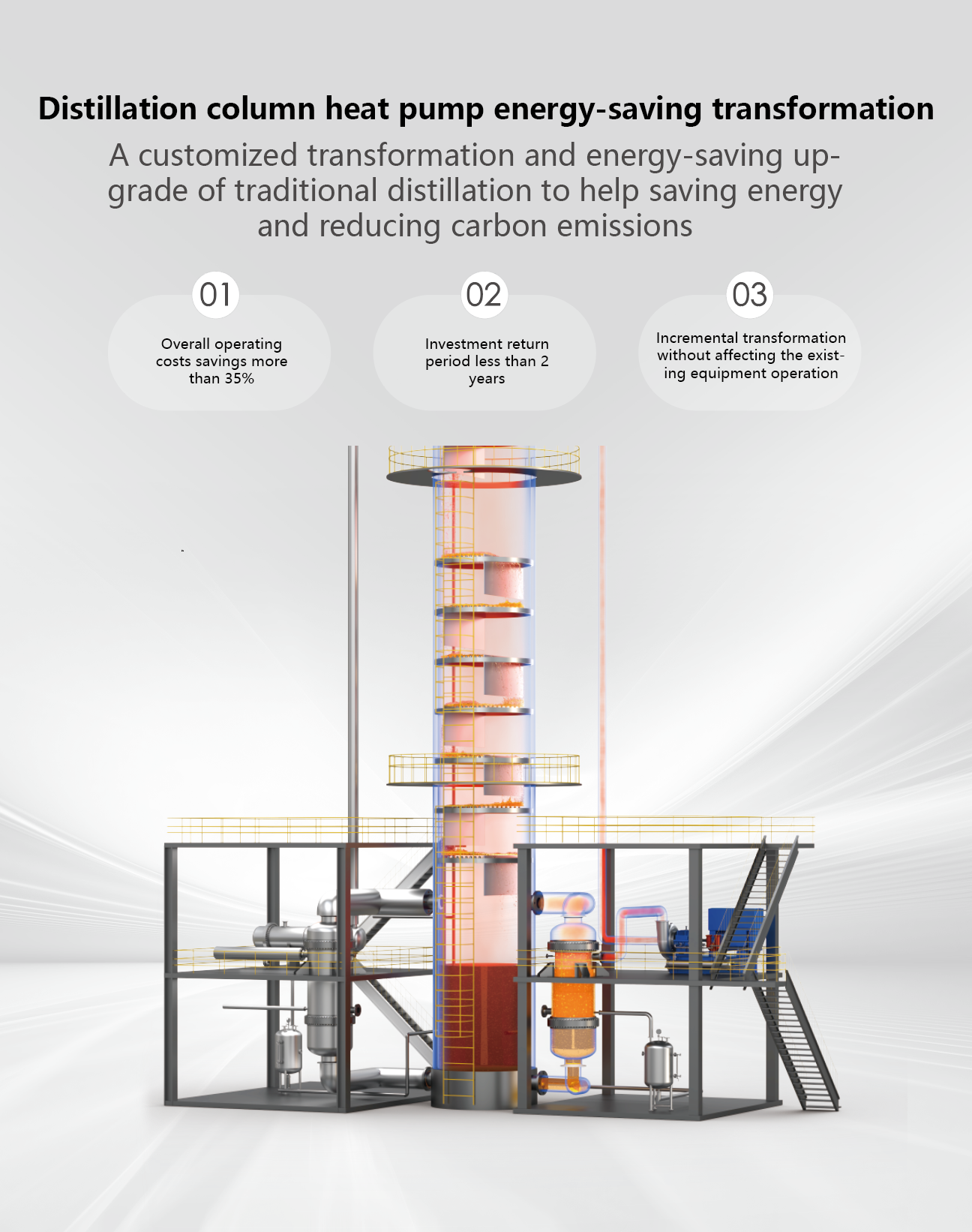

Many years of experienced in pharmaceutical machinery research and development and production, together with Leheng's MVR steam recompression core technology, AGT Group has jointly launched a new generation of energy-saving heat pump Assisted distillation systems, providing customized and efficient energy-saving heat pump Assisted distillation systems solutions, effectively solving the high energy consumption shortcomings of traditional distillation systems, with advantages of good separation effect and obvious energy-saving.

The skip mounted heat pump distillation system based on the Efficient Rotating zigzag Bed(RZB) provides a one-stop heat pump distillation solution for customers. Compared with traditional distillation, The skip mounted heat pump distillation system not only has the advantages of small volume, easy installation, and maintenance, but also has a comprehensive energy saving rate over 50%.

Moreover, the heat pumps energy-saving renovation technology for distillation column can be carried out on the existing distillation equipment for customers, by different types and specifications of compressors. The compressors can be selected according to different working conditions and manufacturing requirements. Without affecting the use of existing equipment, the comprehensive operating costs can savings over 35%.

The achievements of AGT Group comes from the trust and support of our customers. In the future, AGT will continuously contribute to the pharmaceutical machinery field by years of industry accumulation and sedimentation; actively explore, innovate and support the vigorous development of the pharmaceutical machinery industry with high-quality products and efficient services!

We sincerely appreciate all visitors to our booth. AGT Group looks forward to meeting you again!