MVR Forced Circulation Crystallizers

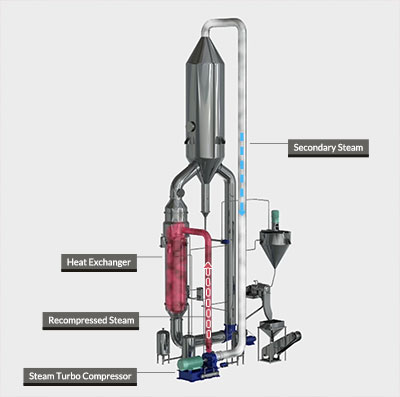

Mechanical Vapor Recompression Crystallizer Working Principle

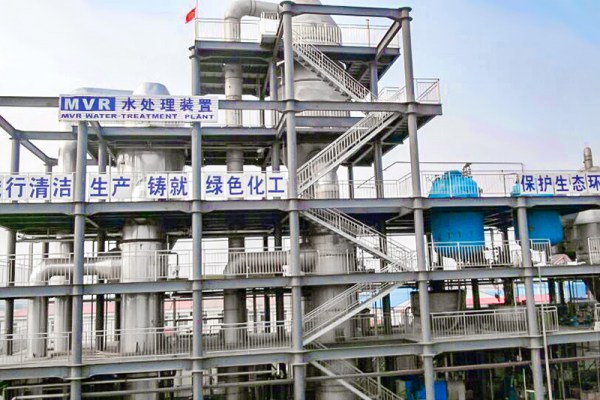

Suitable for chemical wastewater with high salinity, high COD and high boiling point; Suitable for vacuum salt, salt, mineral salt separation of salt industry;

Suitable for Metallurgical industry and environmental protection industry waste water "zero discharge"

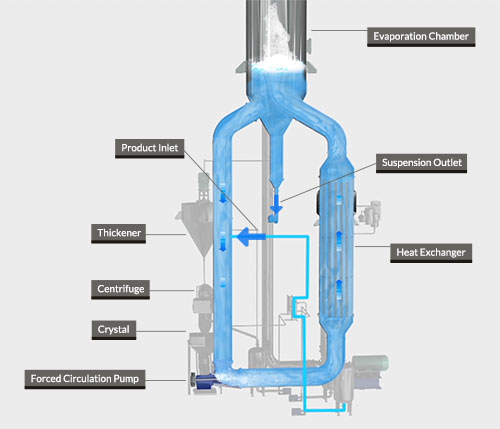

MVR- forced circulation evaporative crystallizer:

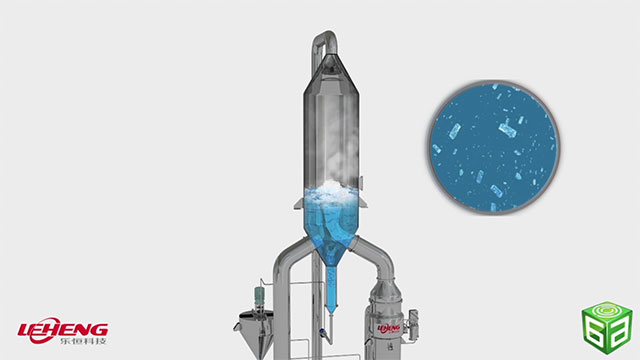

FC crystallizer composed of a crystal chamber, a circulation pipe, a circulating pump and a heat exchanger. The crystallization chamber with a conical bottom slurry discharged from the cone bottom, the circular tube axial flow type circulating pump through the heat exchanger, is heated again into the crystallization chamber, so the cycle, belonging to the slurry circulation type, slurry outlet located near the salt crystallization chamber legs.