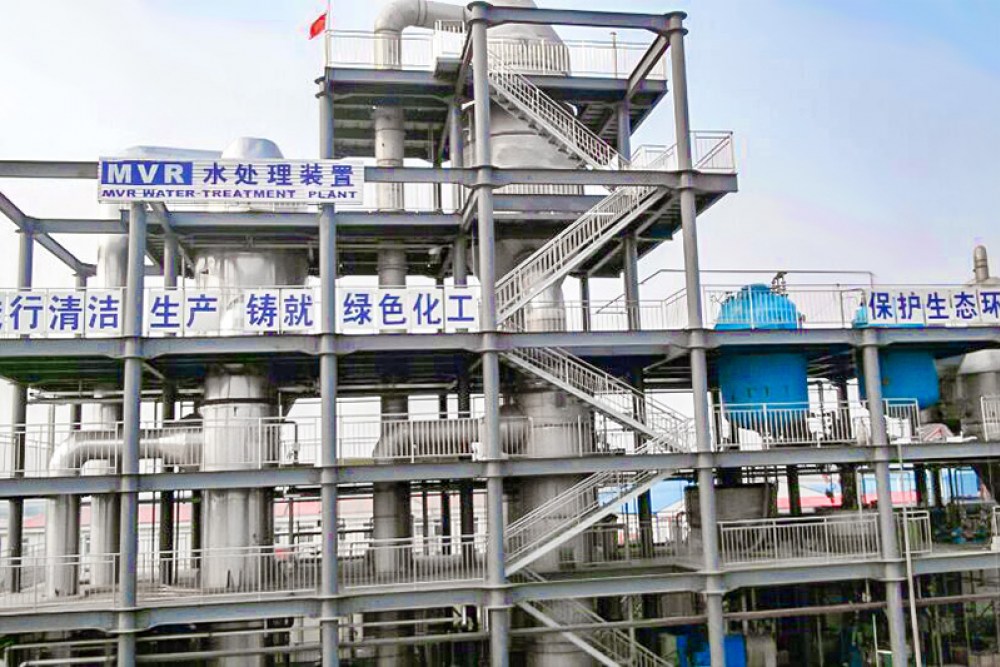

Implementation of the MVR technology solved the tough challenge of high salt content wastewater treatment, water cycle utilization rate of more than 90%; Using photoelectric catalysis for waste gas treatment; Comprehensive recycling and utilization of waste residue, the realization of "three wastes" emissions standards.

Project Information

Energy Consumption Analysis

| Steam Price |

200 |

RMB/T |

Working Time |

8000 |

Hour/year |

| Circulation Cooling Water |

l |

RMB/m³ |

Electrity Price |

1 |

RMB/kW/h |

| Equipment | MVR Evaporator | Three effect evaporator |

|---|

| Centrifugal compressor |

1300 |

KW/h |

1300 |

RMB |

0 |

KW/h |

0 |

RMB |

| Pump |

450 |

KW/h |

450 |

RMB |

400 |

KW/h |

400 |

RMB |

| Steam To Preheat |

0.5 |

T/h |

100 |

RMB |

12 |

T/h |

12 |

RMB |

| Cooling Water |

50 |

T/h |

50 |

RMB |

400 |

T/h |

400 |

RMB |

| etc. |

0 |

|

0 |

RMB |

0 |

|

0 |

RMB |

| Evaporation Cost/ Hour |

1600 |

RMB |

2840 |

RMB |

| Evaporation Cost /Ton |

53.3 |

RMB |

94.6 |

RMB |

| Annual Operation Cost |

12800000 |

RMB |

22720000 |

RMB |

| Cost Saving/Ton |

41.3 |

RMB |

| Ratio of Economy Saving |

43% |