Gearbox type - Centrifugal Steam Turbo Compressor

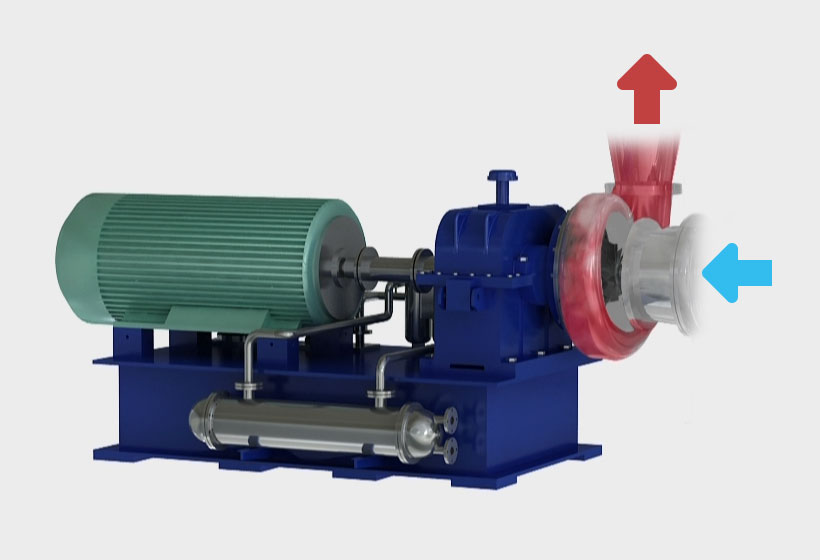

LH Gearbox Centrifugal Steam Compressor Working Principal:

- Gearbox Steam Compressor is driven by motor with speed up gearbox.

- Gearbox drives the impeller rotation, the steam flow out the impeller under centrifugal force.

- Meanwhile, the upstream steam will come to fill the impeller. Because of the impeller’s high speed rotation, the steam flow velocity will be accelerated and leave the impeller.

- The steam flow speed reduced after going through diffuser, kinetic energy is converted to hydrostatic energy, pressure increases and temperature rises.

Centrifugal steam compressor is core equipment with high technology, which play important role in MVR evaporator system. Compared with Roots compressor, centrifugal compressor developed by our company, have many advantages like wide working range, easy maintenance, lower noise and better reliability etc.

Gearbox centrifugal compressor basic parameters:

| Item | Parameter range |

|---|---|

| Mass Flow (MVR system evaporation): | 1~200tons/h |

| Volume Flow: | 3000~280000 m³ /h |

| temperature rise of saturated steam: | 6~24 ℃ |

| Impeller rotation speed: | 5,000~40,000RPM |

| Max. compression ratio: | 3.5 |

|

Remark:

|

|

Centrifugal compressor has two options in design: single stage centrifugal compressor and multi-stage centrifugal compressor.

Single-stage centrifugal compressor main features:

- Compact arrangement of overhung impellers, compressor and gearbox;

- The motor, gear box and the compressor are arranged on the same foundation;

- The volute adopts the casting or welding structure;

- Because of the high speed, the impeller is made of high quality materials such as chromium-nickel steel or titanium alloy;

Multi-stage centrifugal compressor main features:

- Suitable for working conditions with big-flow and high-saturation vapor temperature rise;

- Working together by several stages of impellers on the same axis; or by several sets single stage centrifugal compressors;

- In order to improve efficiency and avoid unbearable high temperature in volute, water can be filled into the channels between the stages of impellers;

LH Gearbox Steam Compressor Technology Advantages:

- Steam compressor volute is usually made from stainless steel casting or welding, with strong corrosion resistance and better stability.

- Impeller made from precipitation-hardening stainless, with more than 1100MPa tensile strength and good corrosion resistance

- In severe working conditions, impeller can also use TC4 titanium alloy with light quality, high strength and good corrosion resistance

- As the core component of steam compressor, impeller is customized according to client’s request. The design of the impeller strictly carries out various mechanical calculations, and the complex processing flow ensures the efficiency and reliability of the impeller

- Advanced end teeth design between impeller and high speed shaft, ensures the better centering effect, and reliable torque transmission.

- According to requirement, guide vane regulating system and frequency convertor is available to ensure the high efficiency of compressor, from 50%~120%; Simple regulating system with easy design, stable working performance and longer lifetime.

Different customers with different process, the same process will have different parameters; our company has various structures of products, with different rotation speed design, with different driven system to meet the client’s requirement.