LH Evaporator

Engineering for energy saving

LH Evaporator

Engineering for energy saving

Products

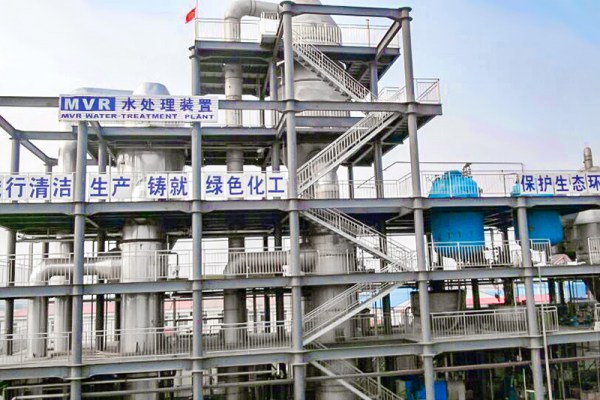

Mechanical vapor recompression (MVR) evaporator & compressor from Leheng

-

首页

-

Products

-

Evaporator & Crystallizer

-

MVR Evaporator

-

MVR Falling Film Evaporator

- MVR Falling Film Evaporator

MVR Falling Film Evaporator

- Pharmaceutical

- Food Service

- Chemical

- Suitable evaporating process for material with high viscosity and concentration, surface film flow with minimum losses

- No need of vapor condenser, simple process, reliable continues operation

- Due to the film flow in the one-way evaporator, heat transfer coefficient is higher

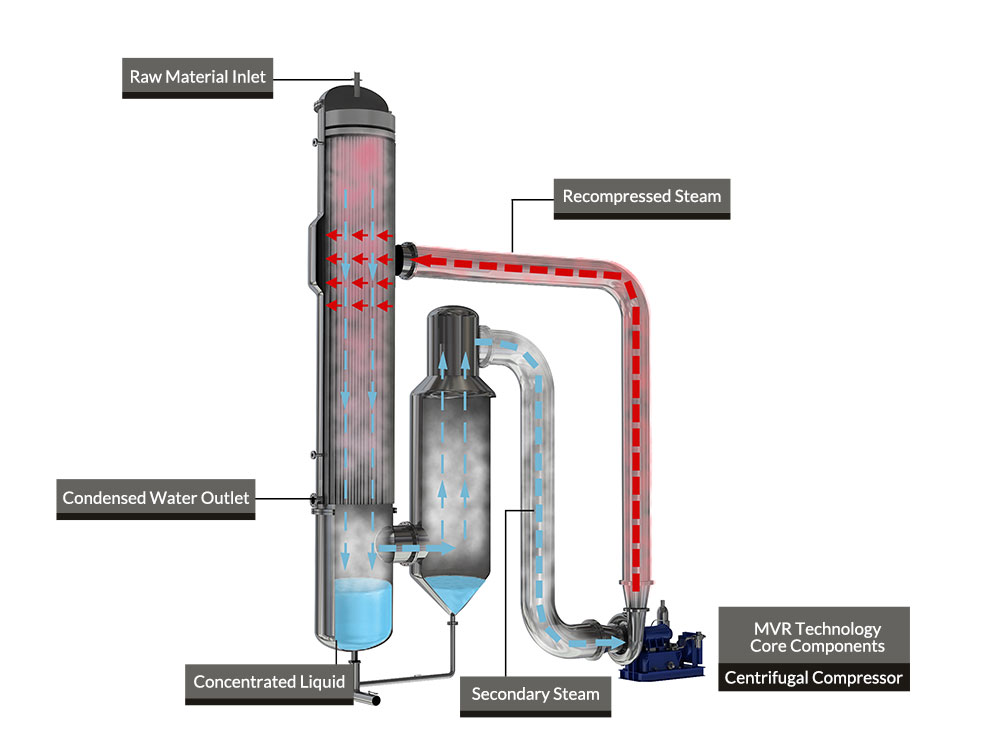

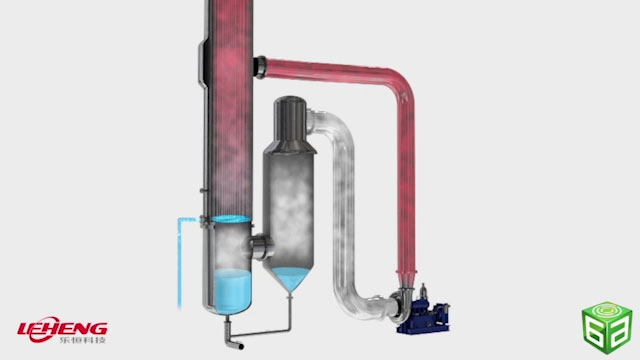

LH Falling Film Evaporator Working Principle

- The material is added from the top of the evaporator and flows along the tube wall under the action of gravity. During the process, the solvent is continuously evaporated so that the solute concentration is increased.

- The finishing liquid is obtained at the bottom of the heat exchanger.

- The used steam enters the steam compressor. After compressor process, the pressure increase and the temperature rise. As a new heat source, heat the material that needs to be evaporated.

MVR falling film evaporator is improved model by MVR technology. By adding steam compressor and necessary match parts, the new model falling film evaporator can significantly increase the work efficiency and reduce operation cost.

MVR falling film evaporator mainly composed of preheater, heat exchanger, separator, vacuum system, MVR steam compressor, cooling system, cleaning system and control system.

Products Features for LH MVR Falling Film Evaporator:

- Suitable evaporating process for material with high viscosity and concentration, surface film flow with minimum losses.

- No need of vapor condenser, simple process, reliable continues operation.

- Due to the film flow in the one-way evaporator, heat transfer coefficient is higher;

- Small heat transfer temperature difference, gentle evaporating process, no scorching, suitable for temperature sensitive materiel.

- Small amount of liquid retention, the falling film evaporator can be adjusted rapidly according to energy supply, vacuum, feed quantity, concentration etc.

- Because material fluids flow only by gravity, not by high temperature differences, they can be evaporated at low temperatures, low temperature difference evaporation is available. Minimum temperature evaporation, can be as low as 45~55°C

- Suitable for foaming material evaporation. The material liquid in the heating pipe is formed into film evaporation. While at the evaporator bottom, most of liquid is pumped out. Only a small part of material liquid enter separator, along with used steam. The whole process does not form too big impact, thus avoiding the formation of foam.

- Short residence time and special structural design can reduce pollution and bacterial growth;

- The effective design of the separator: The effective gas-liquid separation is obtained by controlling flow velocity of the tangential airflow entering separator, Designed to achieve maximum separation performance with minimal pressure drop;

- Use the fully automated CIP system, precise manufacturing ensured no residue and no blind space. None leakage and zero discharge for ethyl alcohol solution evaporating and concentrating.

- Shorten the CIP cleaning time, to help reduce the clean cost.

Main application:

Widely used in medicine, food, chemical, light industry and other water or organic solvent solution evaporation, concentration, concentration, and can be widely used in the above industry waste liquid treatment, especially suitable for heat sensitive materials. The equipment can be operated continuously under vacuum and low temperature conditions, with high evaporation capacity, energy saving, low operation cost, and can ensure the invariance of materials in the evaporation process.